Innovative High-tech Demonstrators

ITQ aims to make engineering and technical courses more attractive to young people. That is why we have been carrying out “fun learning projects” together with universities and their students for more than ten years. The aim is to convey the latest technology in a playful way and to offer young people a completely new approach to technical topics. With our “High-Tech Toys” in study seminars, we inspire the next generation and make the courses more varied and interesting.

Based on the diverse experiences in our student teams, we have been working for several years with the VDMA on various expansion stages of the smart4i Demonstrator, which can be used to illustrate the technical possibilities of digitization and Industrie 4.0. In the meantime, over 100 motivated students from a wide variety of departments and nations have gone through this series of projects and presented them to a large number of well-known representatives from industry and research.

Benefits

Innovative

Our project approaches are always innovative. We create Industrie 4.0 prototypes and demonstrators using the latest methods and tools.

International

In our projects, we work closely with students from all over the world and in cooperation with a large number of universities within and outside of Europe.

Iterative and incremental approaches

When implementing our projects, we always rely on agile methods, which we have expanded accordingly for use in mechatronics (e.g. mechatronic Scrum).

Interdisciplinary

In all projects, the focus is on interdisciplinarity. We combine different approaches and methods from different disciplines.

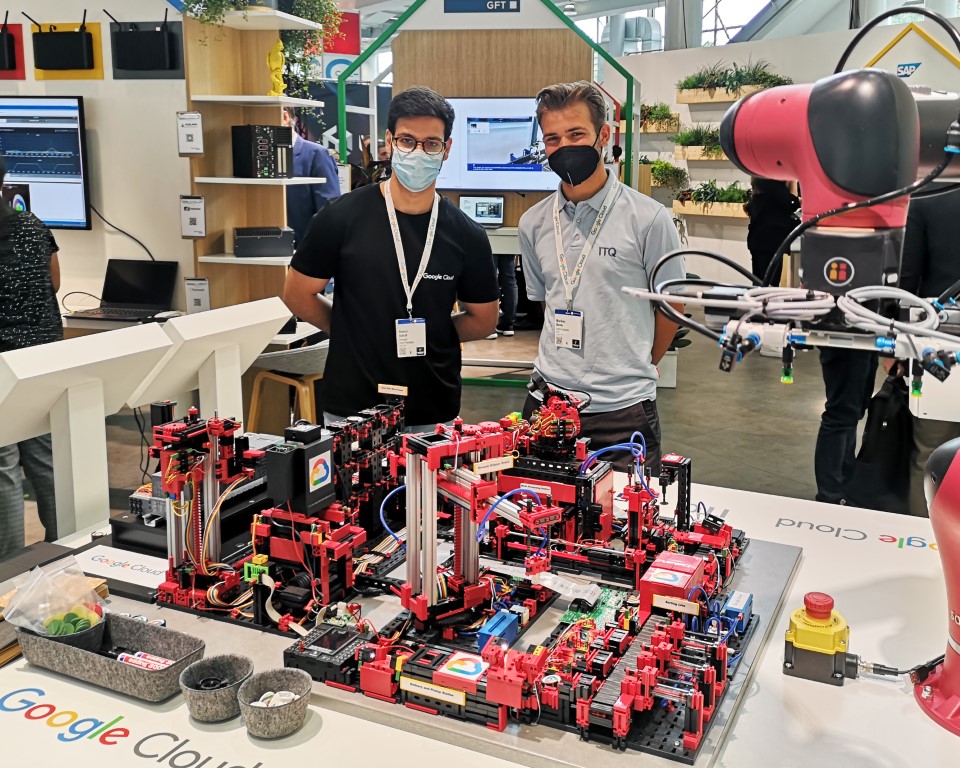

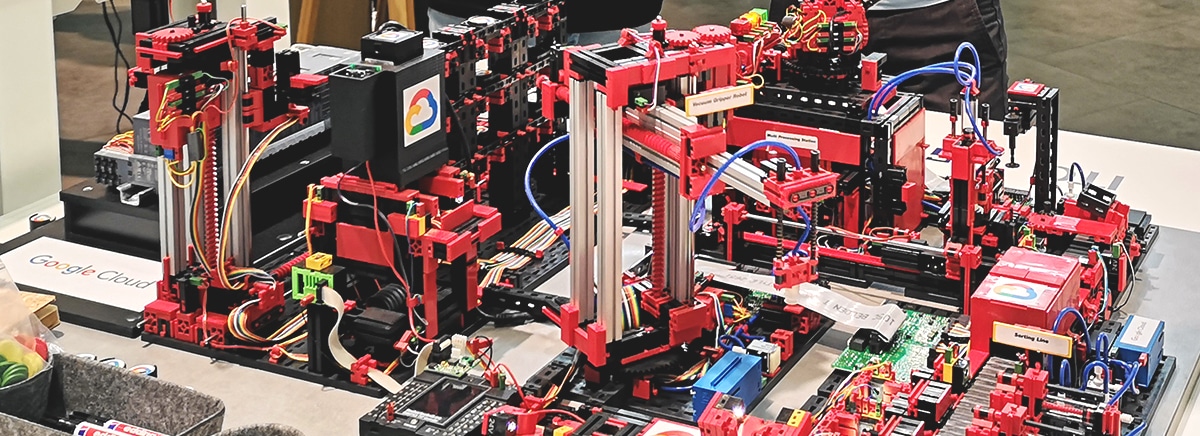

GOOGLE CLOUD DEMONSTRATOR

Google Cloud hands-on experience – Made by ITQ

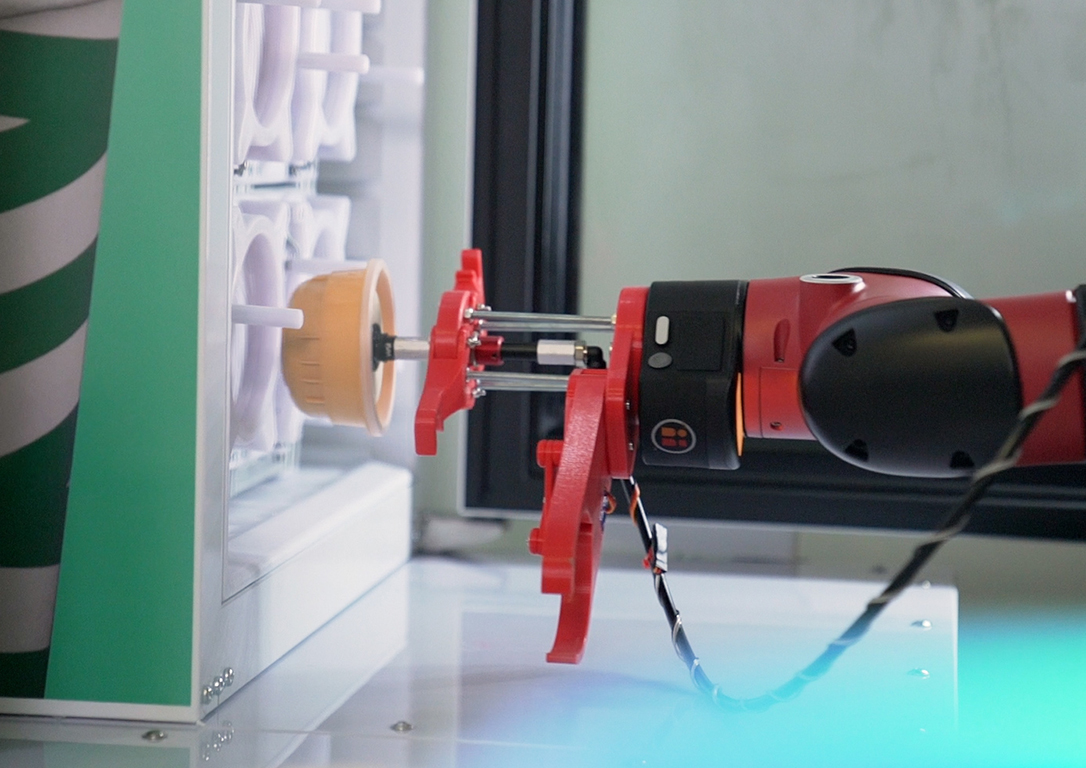

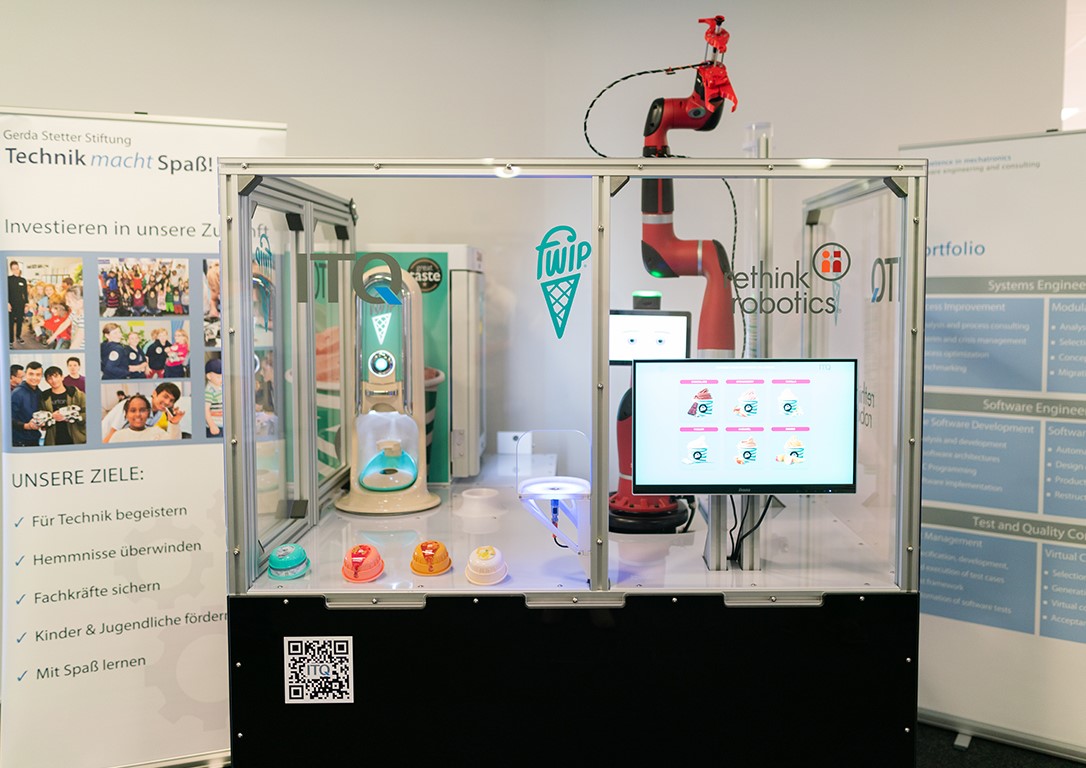

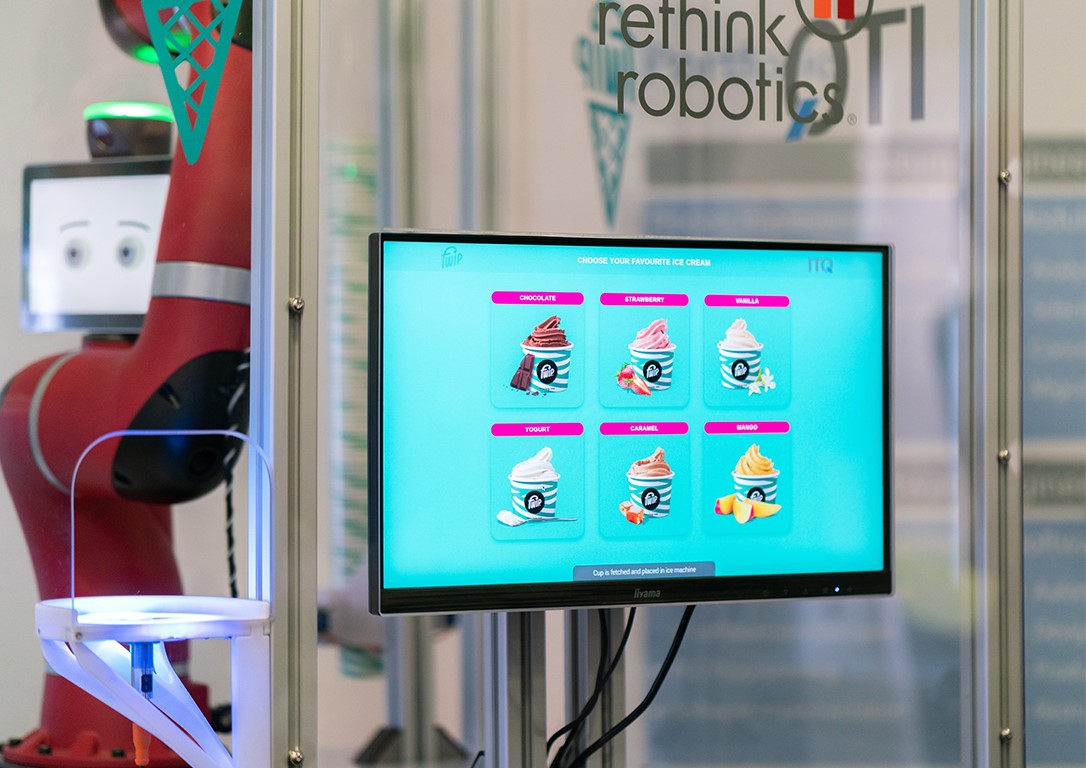

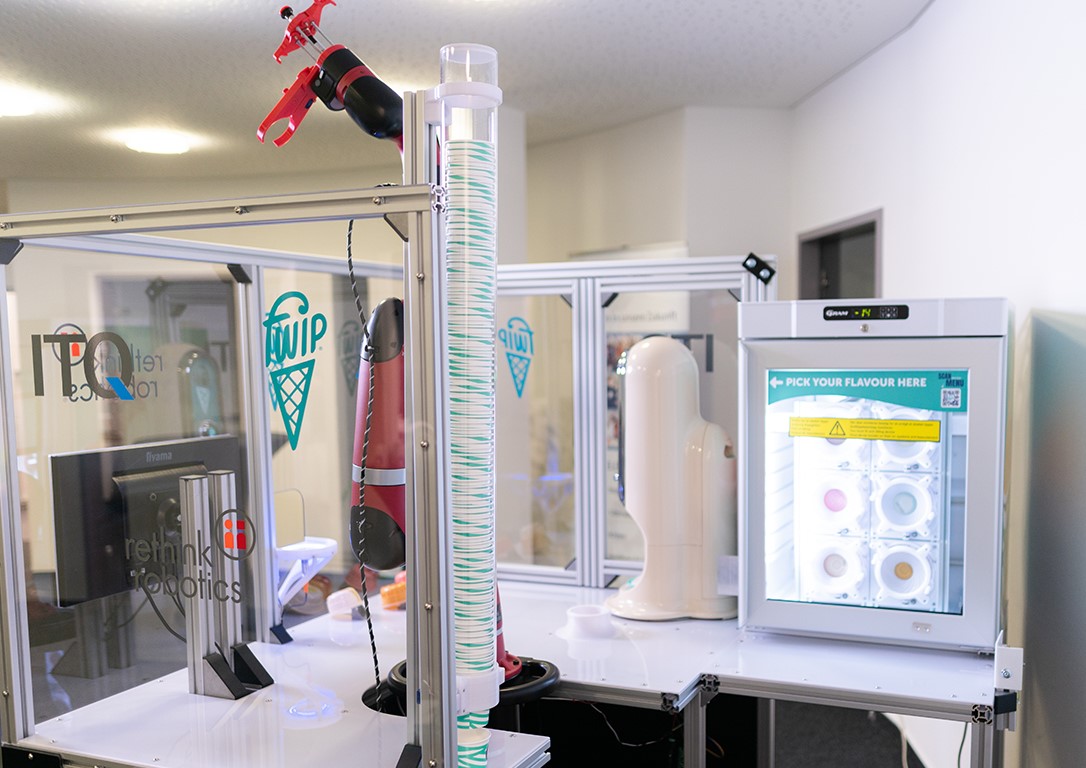

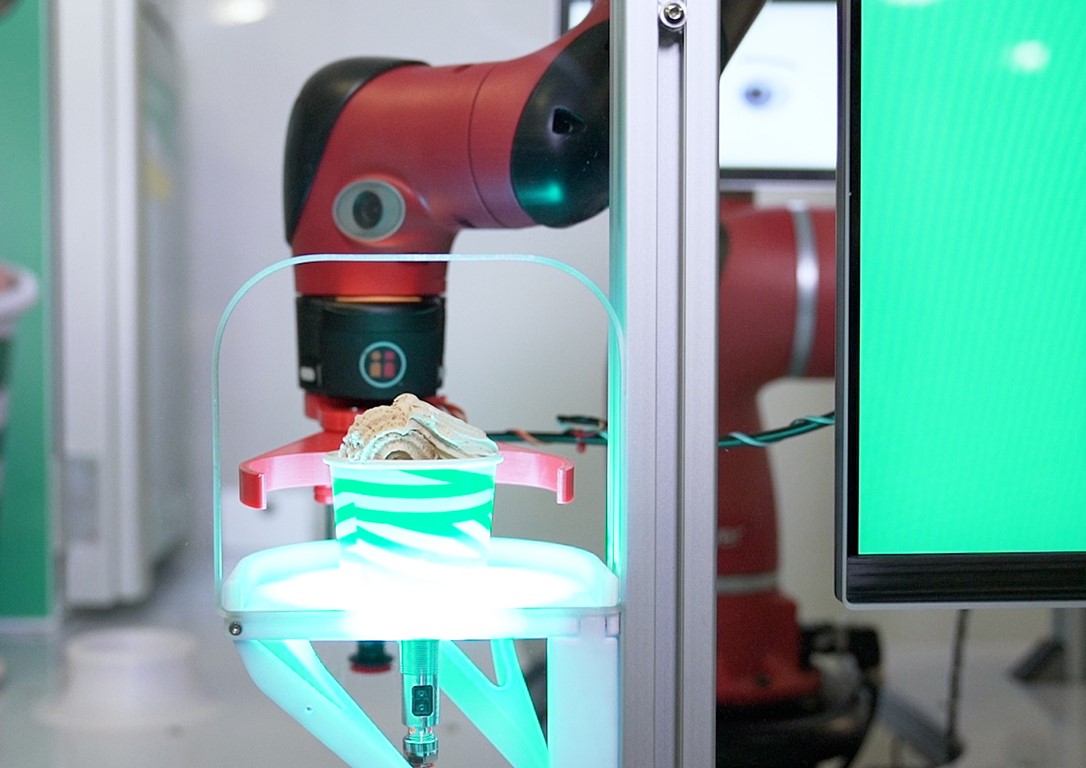

The educational project “Intelligent Fwip Ice Cream Demonstrator” shows the latest technological standards in the field of intelligent automation and collaboration of robots. The task was to equip a “Portobello”, the IoT ice cream machine with capsule system from Fwip, with new motors and sensors and to enable intelligent operation with the help of a “Sawyer” Robot from Rethink Robotics. Two student trainees worked on the project, who, in addition to engineering, were also able to deepen their practical experience in project management and 3D printing.

The automatically controlled robot takes an empty ice cream cup with a gripping hand and places it under the dispensing point of the machine. It then uses a vacuum gripper to take the desired ice cream cartridge from the cooling device and places it in the Fwip ice cream machine. This then prepares the ice cream. In the final step, the robot arm removes the prepared ice cream and serves it to the user at the dispensing point. The entire process of ice cream preparation is made visible to the viewer with the help of neopixels.

FWIP ICE DEMONSTRATOR

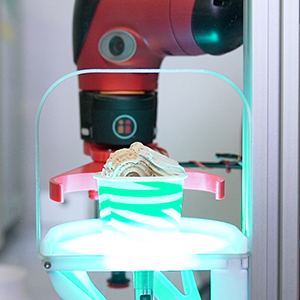

Collaborative robots – The intelligent ice cream machine

The educational project “Intelligent Fwip Ice Cream Demonstrator” shows the latest technological standards in the field of intelligent automation and collaboration of robots. The task was to equip a “Portobello”, the IoT ice cream machine with capsule system from Fwip, with new motors and sensors and to enable intelligent operation with the help of a “Sawyer” Robot from Rethink Robotics. Two student trainees worked on the project, who, in addition to engineering, were also able to deepen their practical experience in project management and 3D printing.

The automatically controlled robot takes an empty ice cream cup with a gripping hand and places it under the dispensing point of the machine. It then uses a vacuum gripper to take the desired ice cream cartridge from the cooling device and places it in the Fwip ice cream machine. This then prepares the ice cream. In the final step, the robot arm removes the prepared ice cream and serves it to the user at the dispensing point. The entire process of ice cream preparation is made visible to the viewer with the help of neopixels.

More Information:

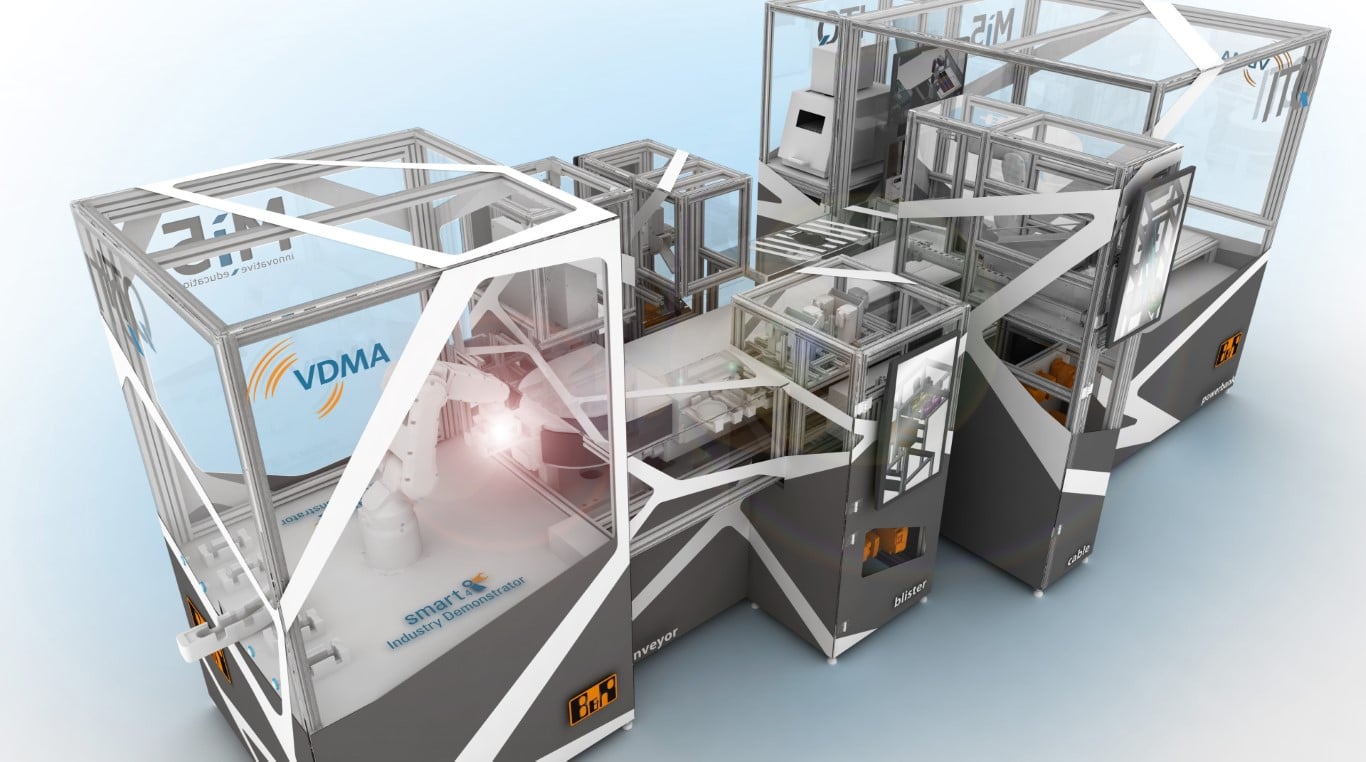

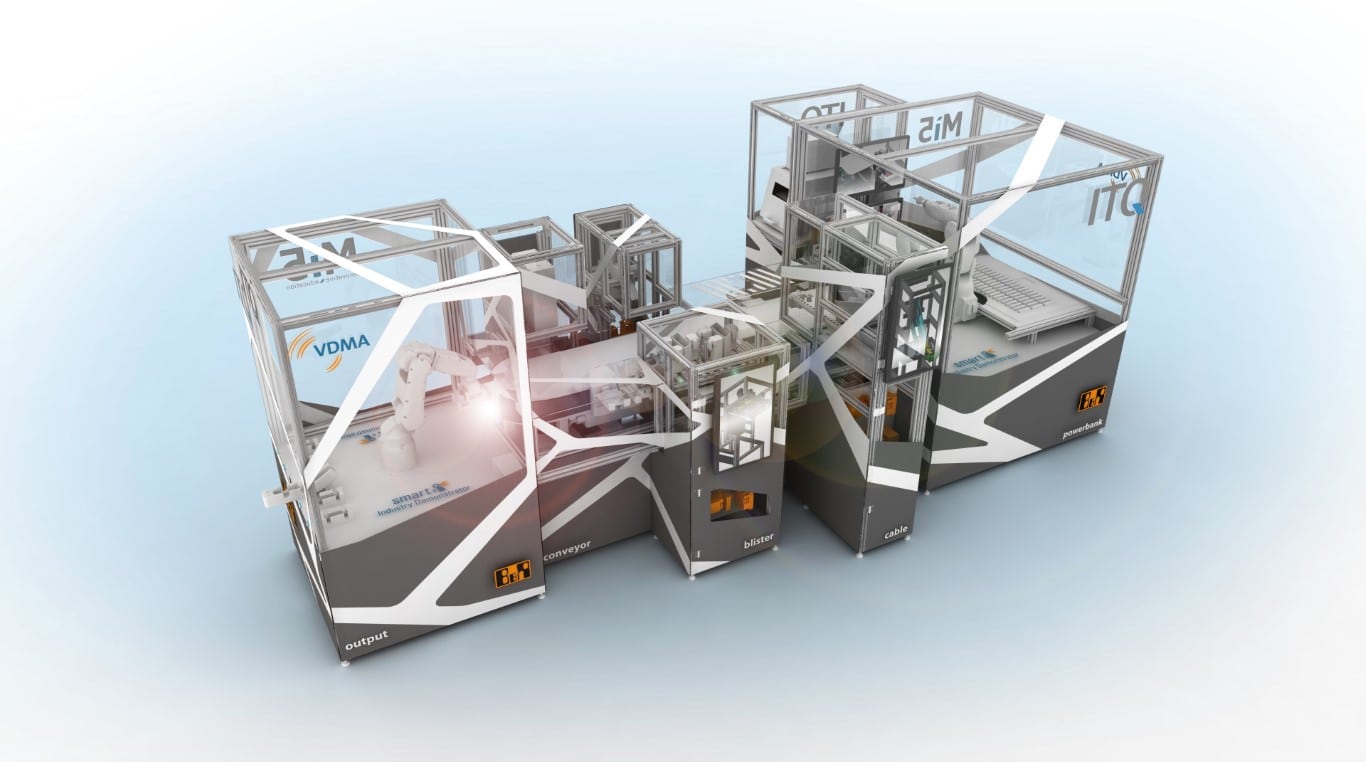

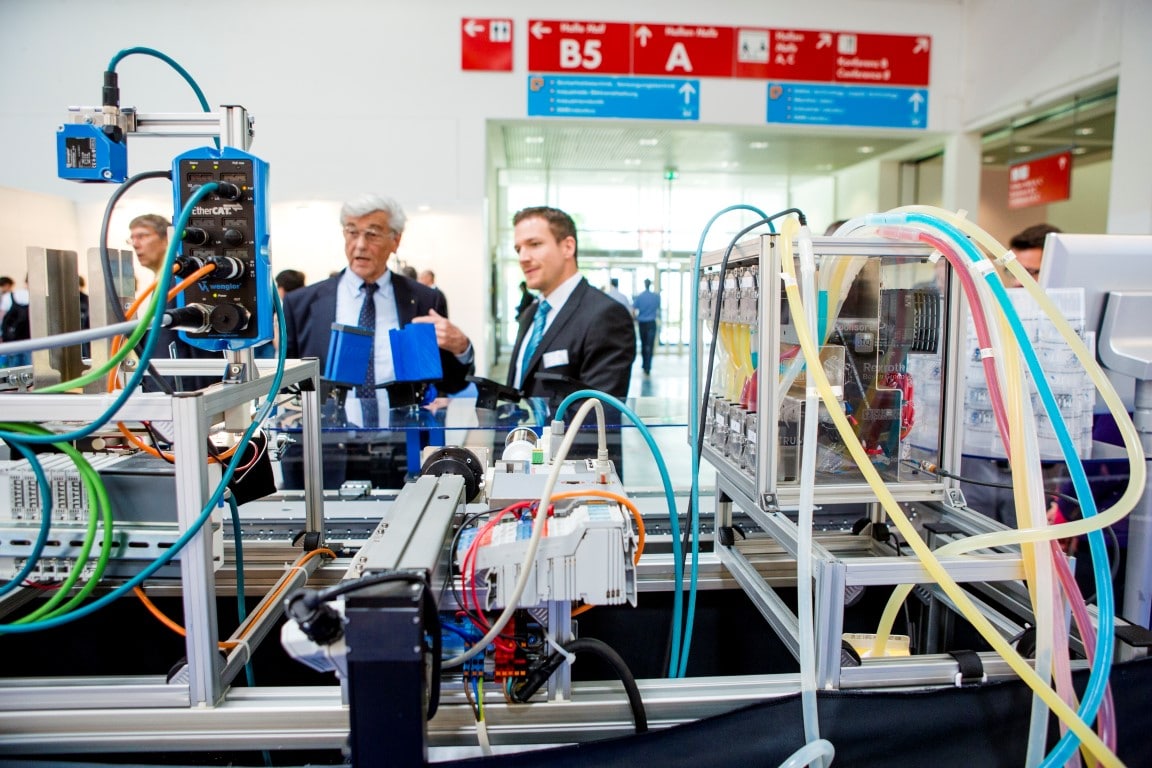

smart4i Demonstrator

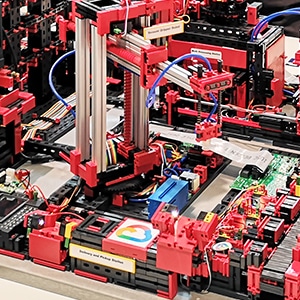

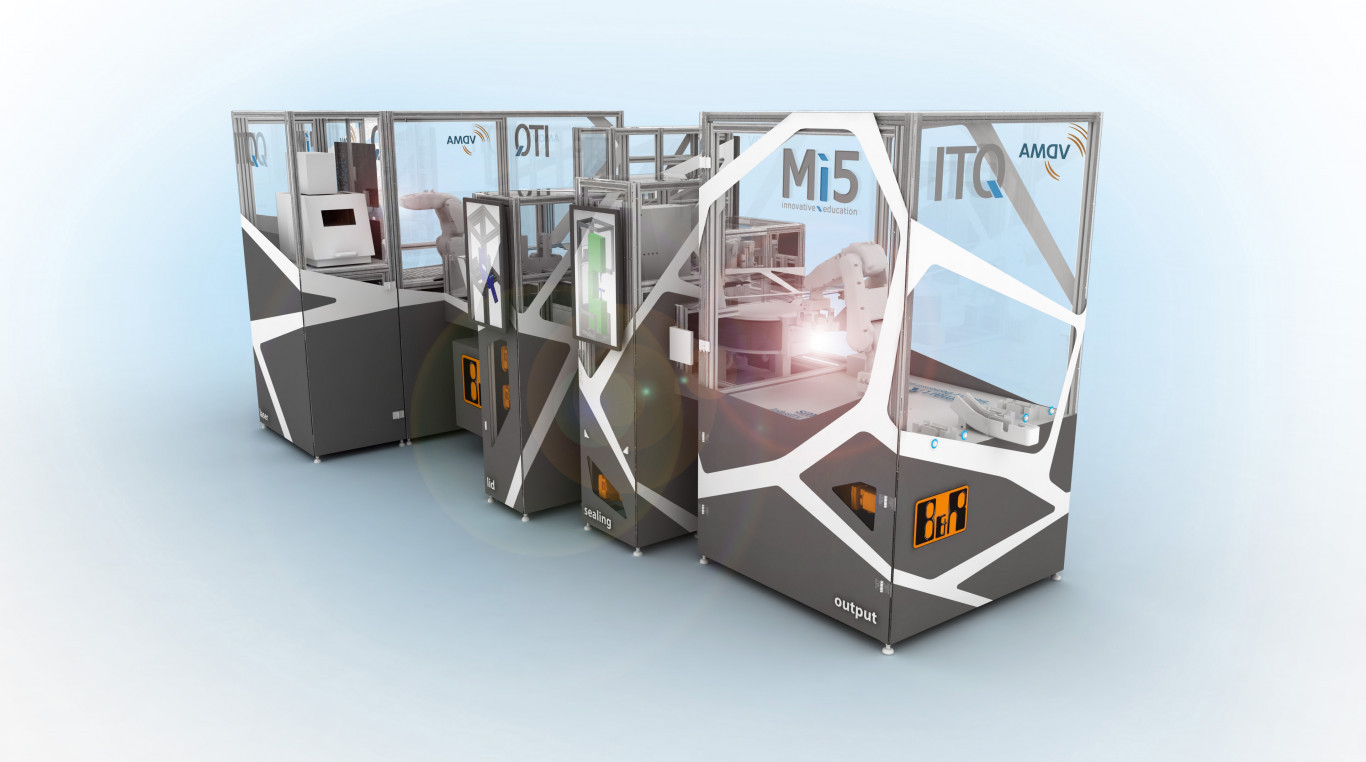

From the Cloud to the Personalized Power Bank

The smart4i Demonstrator makes Industrie 4.0 tangible and proves that manufacturing processes can be made Industrie 4.0 compatible by efficient use and combination or technological components. By means of the smart4i Demonstrator, customers have the option of ordering an individualized power bank. Color, wrapper and label can be adapted to the customer’s personal preferences and wishes.

Your order is immediately processed by the demonstrator and the parameters relayed to the modules. The distinctive feature is the consistent crosslinking from the cloud to the field devices, which is ensured at all times by unified interfaces (OPC UA) and information models. The smart4i Demonstrator was implemented in only 36 weeks by an interdisciplinary and international team of 36 students in cooperation with industry partners.

More Information:

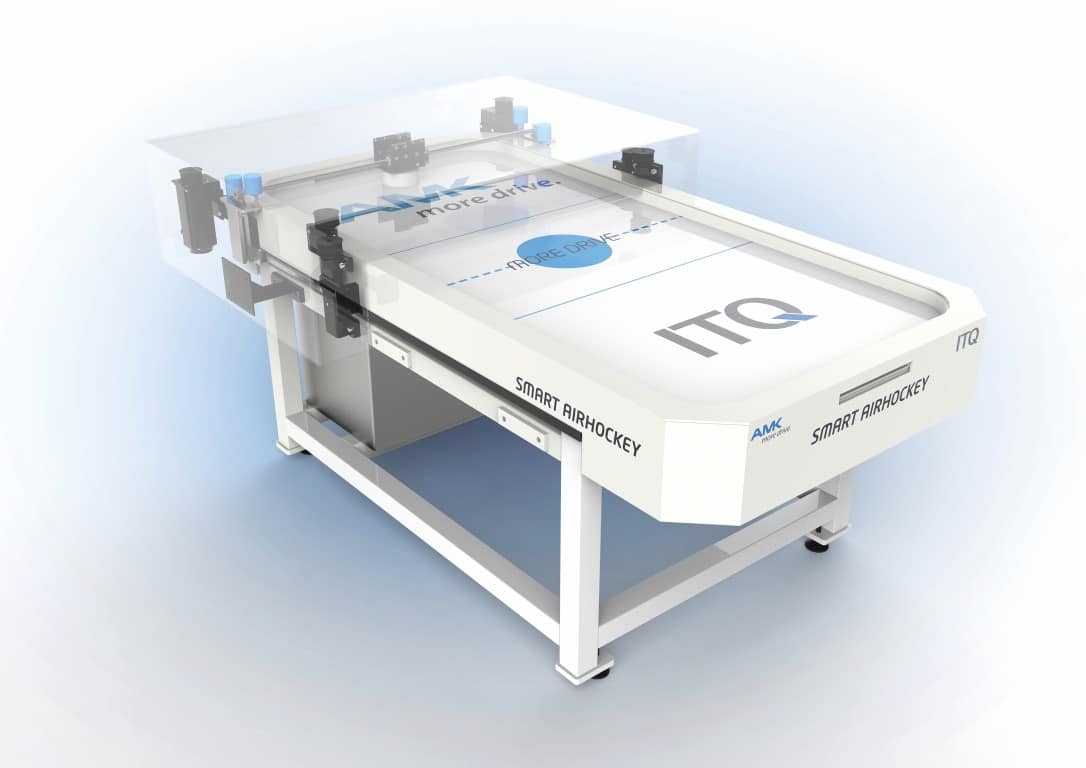

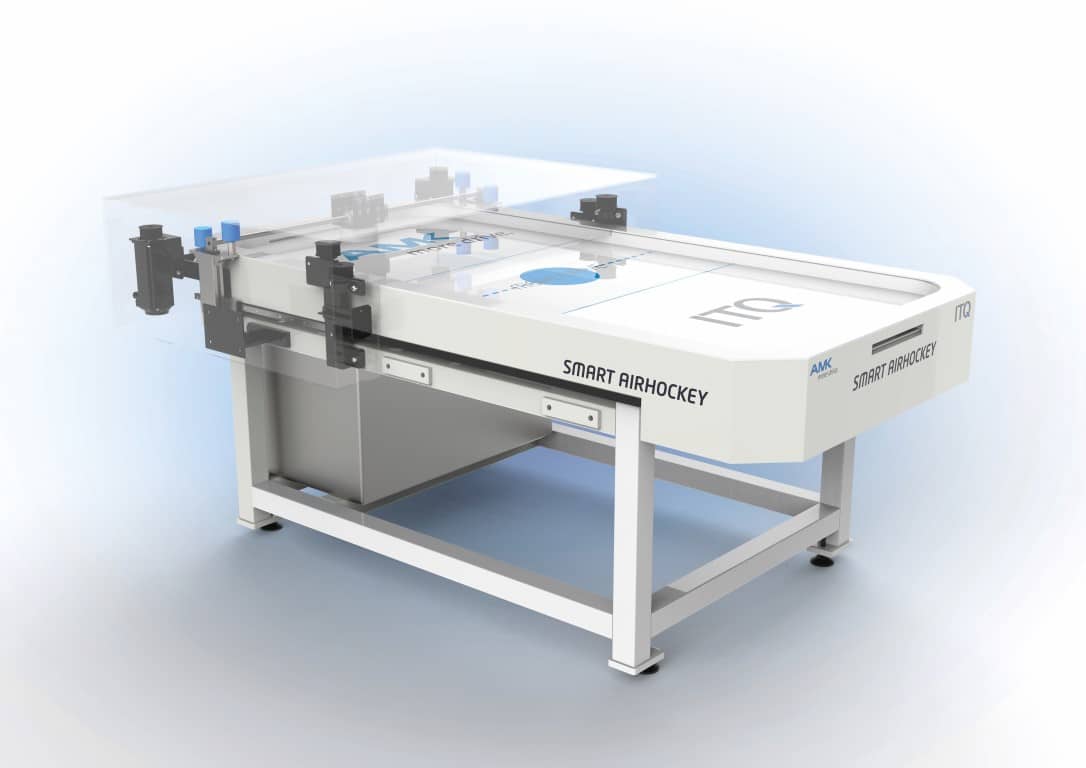

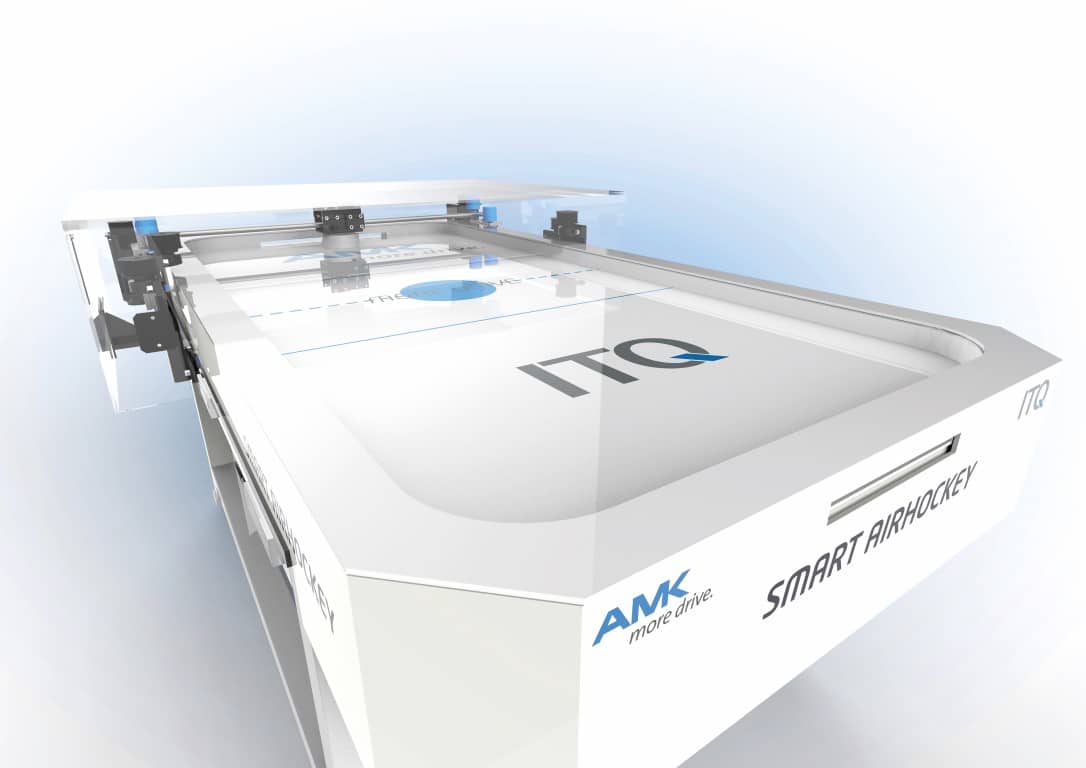

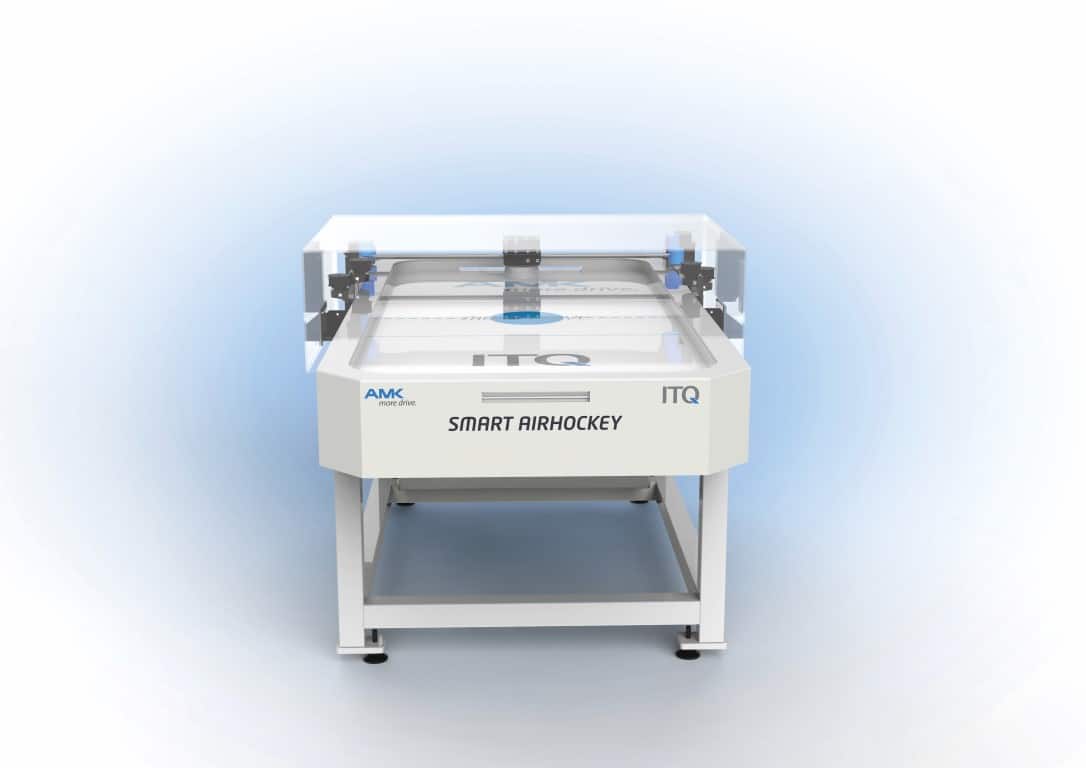

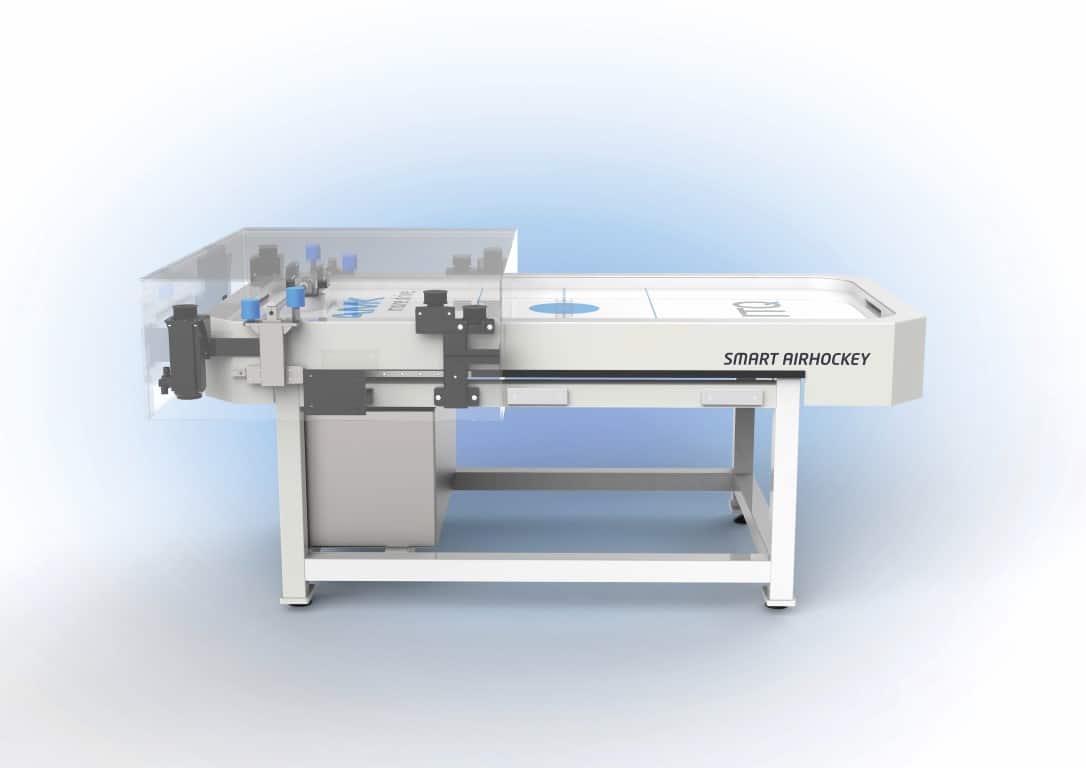

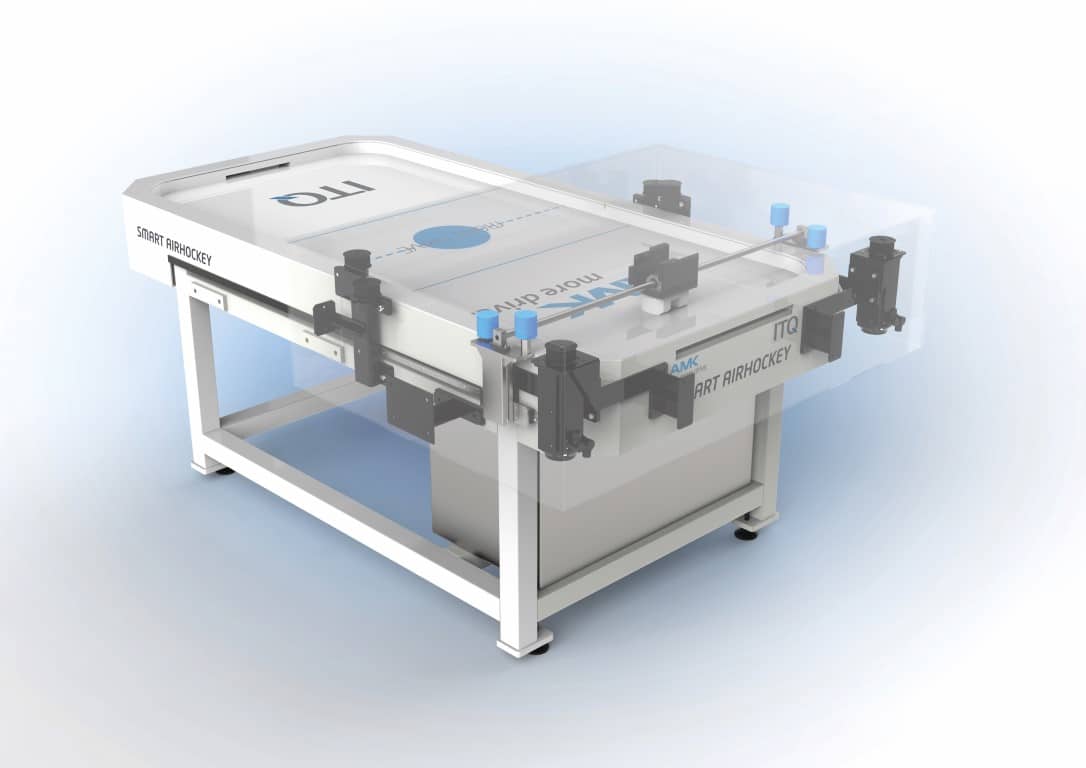

Smart Airhockey Demonstrator

Artificial Intelligence through Machine Learning

With the new Smart Airhockey Demonstrator, an impressive trade fair demonstrator has been implemented that presents “machine learning” with a fun factor. The joint project by AMK and ITQ is a model example of today’s engineering and was continuously developed in iterative steps by an international and interdisciplinary team of students in close cooperation with Aalen University within six months.

With the new Smart Airhockey Demonstrator we want to show how IoT and automation-related drive components are linked to one another. The aim is to expand the range of IoT and automation-related demonstrators and thus to illustrate the ubiquity of IoT in everyday life. With the help of camera systems, the movement path of the puck is recorded and the shuffle stick moves at lightning speed with the help of the AMK drive motors to defend its goal – a playful battle at the highest level!

More Information:

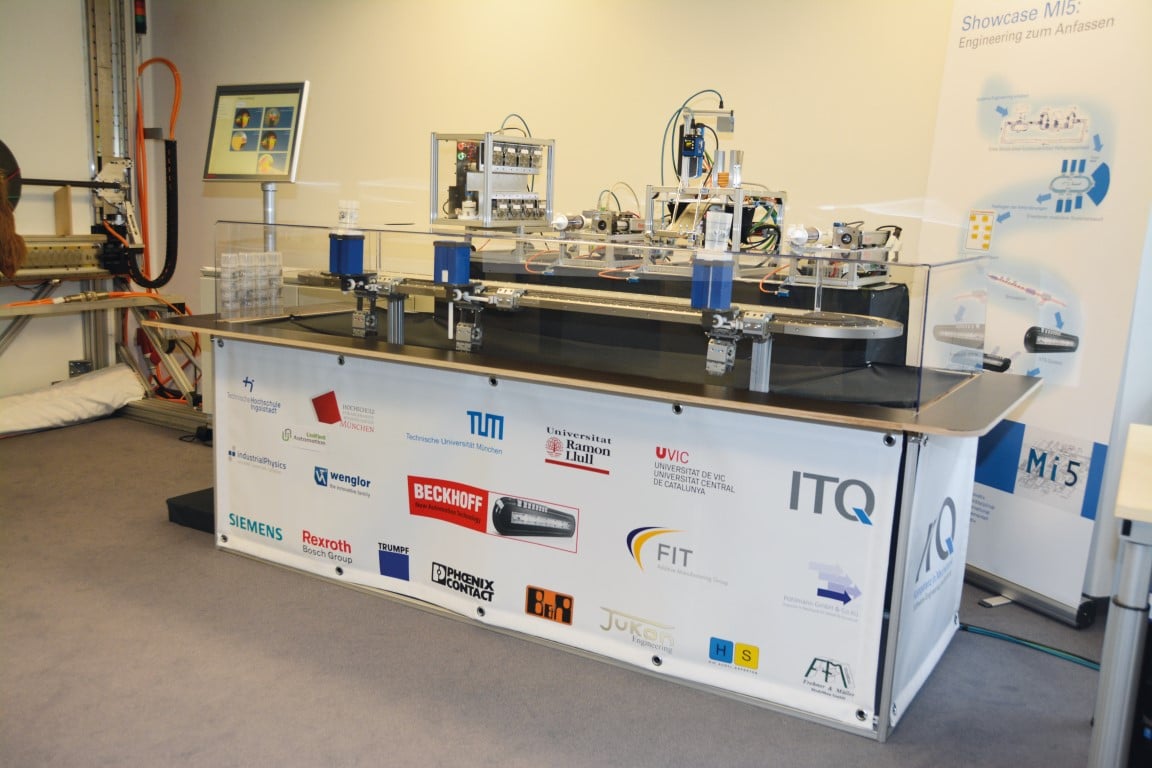

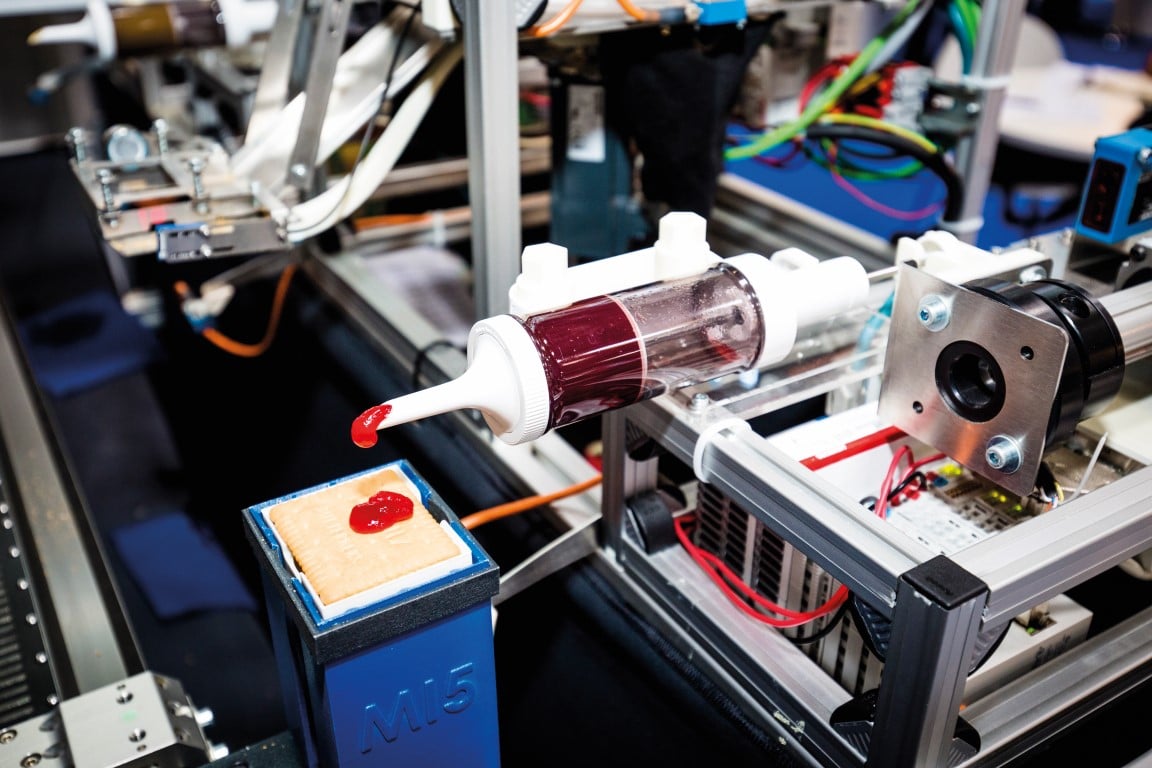

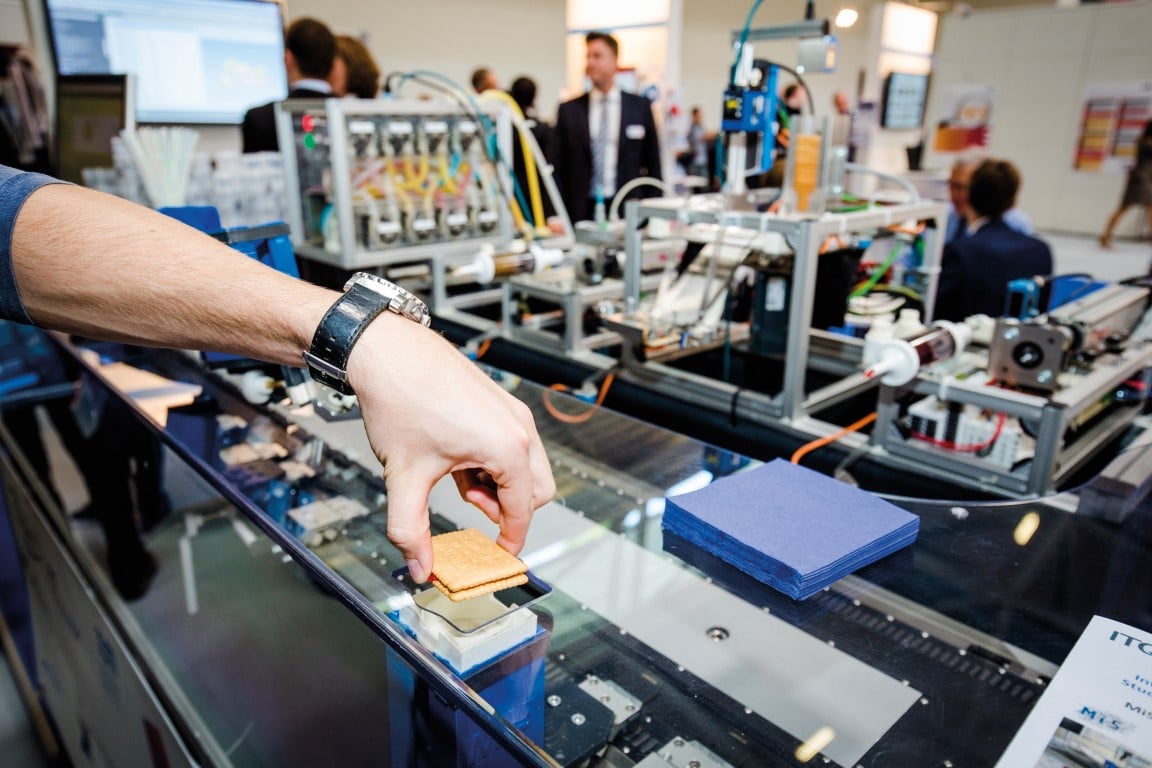

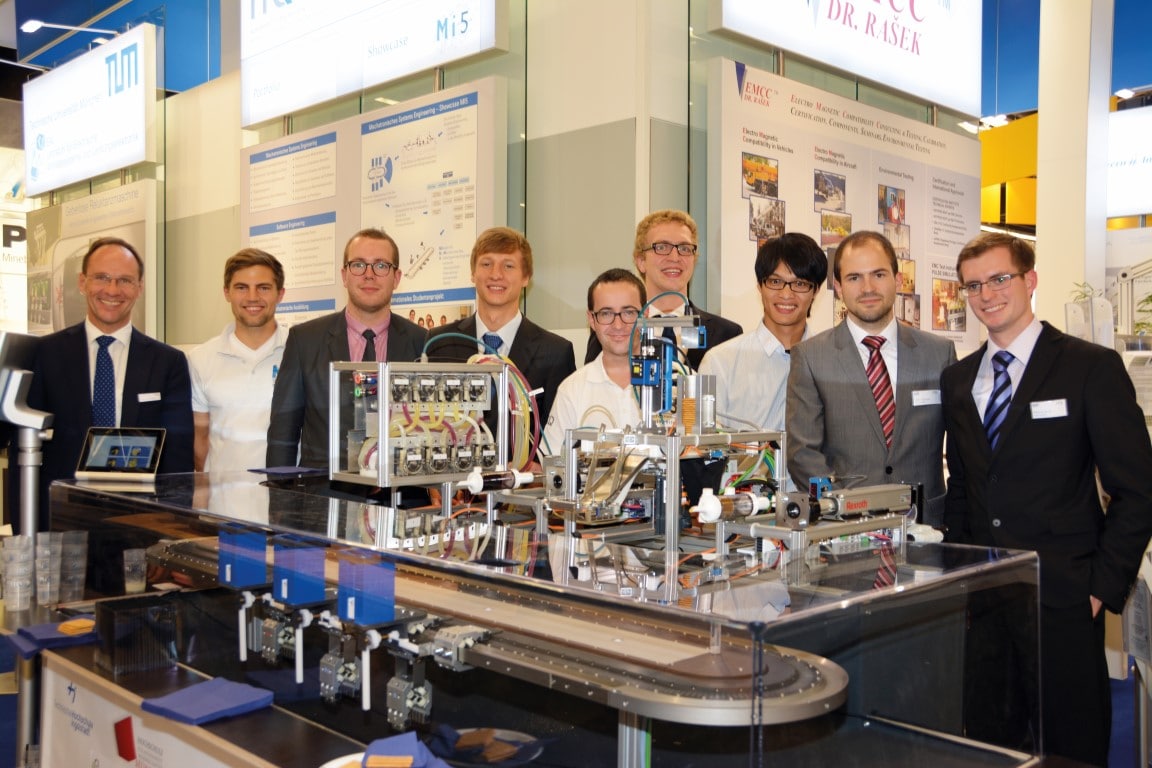

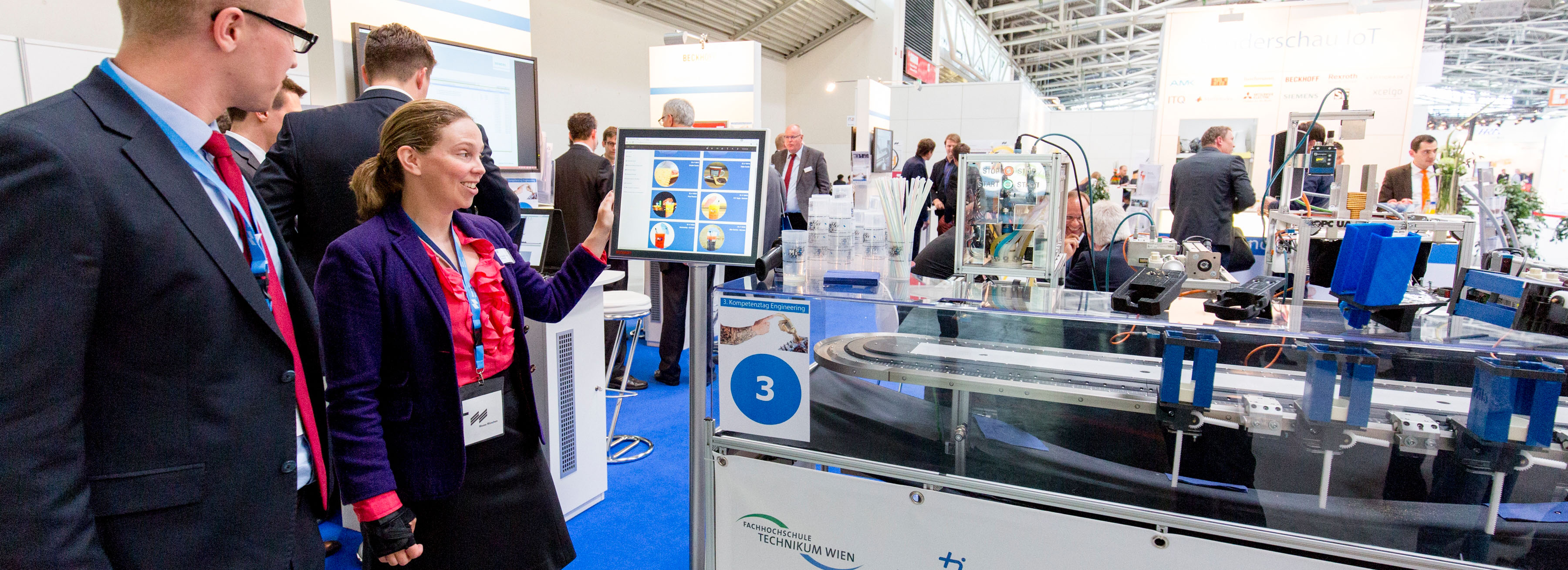

Mi5 Showcase

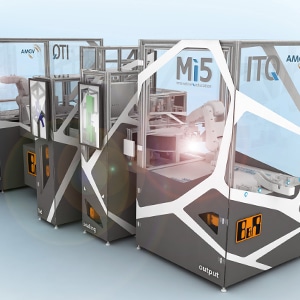

Tangible Engineering

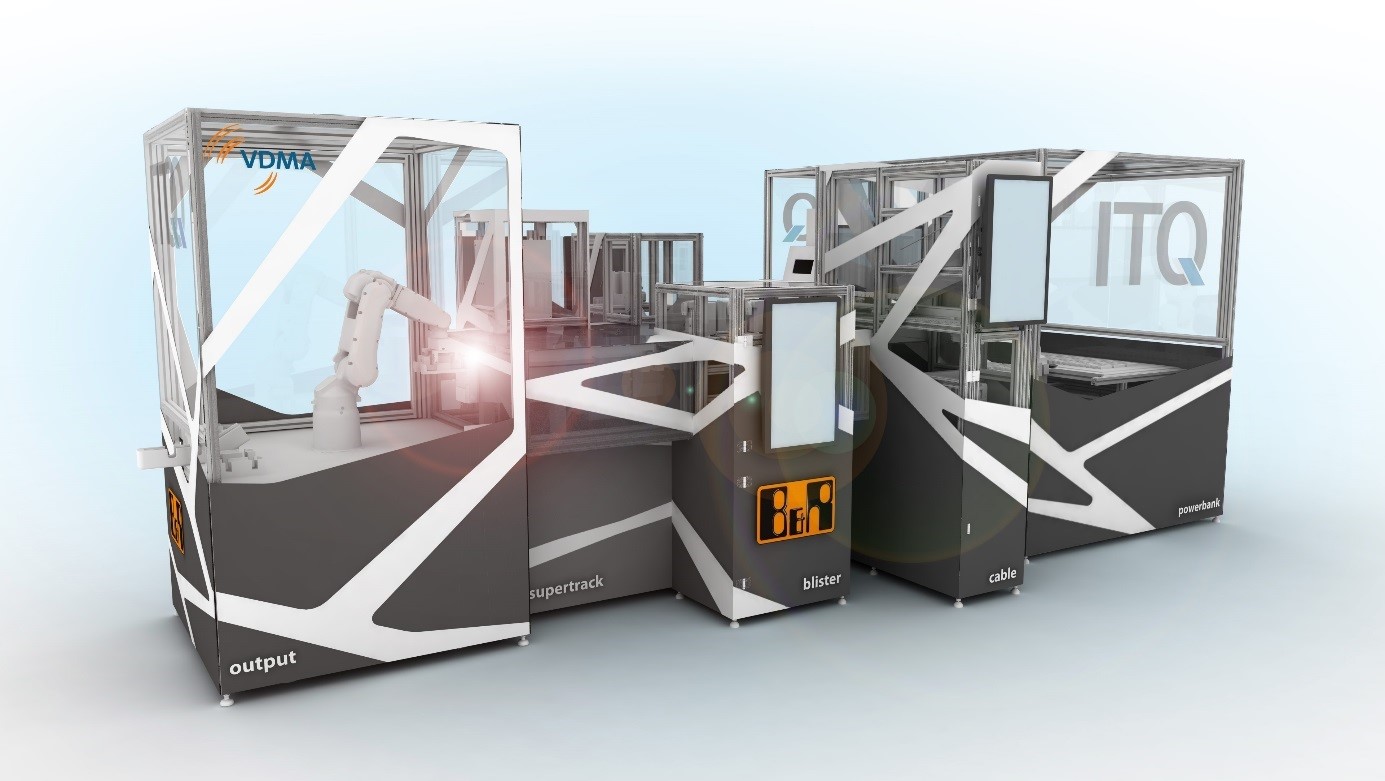

An interdisciplinary and internatonial team of 20 highly motivated students from different fields – e.g. mechanical engineering, electrical engineering, computer science – and from different nations – among them Germany, Switzerland, Italy, Spain, Tunisia, and China – have carried out the project “Showcase MI5” together with partners from industry, research, and education.

MI5 stands for “mechatronic, ideal-typical engineering” fulfilling the following 5 i’s: innovative, interdisciplinary, incremental and iterative. This “engineering demonstration plant” was built virtually and as a real machine, and presented for the first time in 2014 at the trade fair SPS IPC Drives. It also visualizes the concrete individual steps of the engineering.

More Information:

Mi5 Dartboard

Highspeed Dartboard

Who doesn’t dream of always hitting bullseye? That is possible with the High-Speed Dartboard. A dartboard of 450 grams is accelerated with 12 times gravity (g) and decelerated with 30 g, resulting in a movement of up to 50 cm in 100 ms.

In order to make the dartboard not just move quickly, but move to the right position, the dart, which typically stays in the air for 300 ms, is tracked and traced during the first 100 ms, then, from this information, the impact spot is predicted and the traverse coordinates calculated. If you want to feel like “always” achieving your goal, you can experience that at our facility in Garching.

More Information:

Limoweb

State of the Art Loom

To weave sounds – yes, you have read correctly. In this project, a state-of-the-art loom with up to 600 woofs per minute has been remodeled to allow changes of the weaving pattern on the fly, that is, at full production speed. Full production speed means that a thread thinner than a typical human hair is accelerated to a speed of 290 km/h in less than 100 ms.

The thread suffers an acceleration of 1,800 g, and 1 km thread is run in per minute. In order to allow visitors to experience the flexibility of production, the loom was coupled with an oversize keyboard. Each key is assigned a specific thread color and a specific weaving pattern, so a tune played on the keyboard is immediately translated into a texture. So, using this plant, you can literally weave sounds.

More Information:

RACING TRACK FOR SINGLE CHILDREN

Modified Slot-Car Racing Track

The task of the student team was to modify a slot-car racing track in a way that you can compete in a race against a computer – making the system suitable for single children – and lap times and high scores can be visualized. To allow the computer opponent to brake before curves and constrictions, position and speed of the vehicle must be measured.

For this, the track – on a length of 6.4 m per lane – was equipped with 104 sensors in total. Miniature fork light barriers detect whether the vehicle’s fin passes the sensor. As you can see from the technological data, the basic requirement, which sounds playful at the first moment, quickly turns into a manifest mechatronic challenge.

More Information:

Pinball with brains

Pinball Machine with Intelligent Control

The development of a pinball machine with intelligent control was the task of a student team at the University of Erlangen. The 10-headed team had to manage the problem themselves, find sponsors, and develop hardware and software.

Besides expertise in the areas of mechanics, drive technology, image processing and visualization, especially marketing and project-management know-how were needed. Exclusively components built by the project sponsor Siemens were used.

More Information:

GET IN CONTACT WITH US!

Make an appointment with us to find a suitable solution

for your project together.